Compressed Air Training

"It is the level of engagement and training of personnel that separate the Best in Class companies from the rest. The level of training determines the amount of compressed air waste you are willing to allow. This on-line course creates awareness and un-locks the potential of the people that work directly with machinery and equipment - the investment is normally paid for within the first week"

Compressed Air Training

"It is the level of engagement and training of personnel that separate the Best in Class companies from the rest. The level of training determines the amount of compressed air waste you are willing to allow. This on-line course creates awareness and un-locks the potential of the people that work directly with machinery and equipment - the investment is normally paid for within the first week"

“You have put the course on the right level. The content covers all the main aspects you need to know about compressed air without going into too much detail. It makes it very useful for a very broad category of users. Very good, I will definitely recommend this course to energy and safety personnel on our sites!”

COMPRESSED AIR: A SHORT INTRODUCTION

The goal of the compressed air training is to achieve direct results in the areas of energy savings, environment, safety and the working environment. To do the on-line course is the most cost effective measure you can do to achieve results both short and long term. Your personnel are your greatest source of potential. The on-line course creates awareness and un-locks the potential of the people that work directly with machines and equipment.

Compressed air is often referred to as the hidden utility with the most energy saving potential. It is in most plants the most expensive media to use due to its extremely low efficiency. Only 5-6% of the total power input becomes useful mechanical energy. Consequently, all forms of reducing compressed air usage have an unusually high return in forms of reducing both energy and CO2 emissions. The safety aspects surrounding compressed air are often forgotten despite the serious consequences of misuse. The course explains the safety issues and provides guidelines for working safely with compressed air.

MOST PROFITABLE MEASURE

Compressed air training is the most underestimated and at the same time most profitable measure a company can take. For example, fixing a single air leak is worth hundreds, in many cases thousands of dollars. Making personnel aware of this - generate immediate savings.

OPTIMISATION

As with leakages, raising personnel awareness of various ways of reducing air consumptions creates motivation to assist. The course provides numerous, easy practical examples of what can be done.

INCREASED SAFETY

Compressed air is considerably more dangerous than most people think. All personnel that come into contact with compressed air require training.

An Environmental Issue

An Environmental Issue

THE CARBON FOOTPRINT OF COMPRESSED AIR

To produce compressed air is a very inefficient process, only 5-6 % of the total power input is converted to usable mechanical energy. That makes it easier to understand why compressed air generally is the most expensive media a company uses. Consequently, what appears as minor compressed air savings are in reality substantial power savings. If we can save energy we reduce our carbon footprint. Virtually all operators and technicians either use or come into contact with compressed air. With some simple guidelines and motivation you can turn them into great contributors to the reduction of your compressed air usage. Understanding the environmental aspects of compressed air is an important part of the energy saving process.

Safety

Safety

“In less than an hour the on-line course will give you and your co-workers all necessary information of what compressed air is and how it is used. It also goes through the risks involved in the misuse of compressed air and provides ideas and suggestions to create a better and safer working environment. Everyone that comes into contact with compressed air should do the on-line course”

SAFETY

Many people still work under the impression that compressed air is just like the air we breathe and is completely safe. This is a major part of the problem. Air at atmospheric pressure is safe and odourless. Once the air is compressed it is a completely different matter as it contains considerable force. It is this force that allows you to power- tools, actuators that lift and push enormous weights, brakes to vehicles and trains. To be able to work safely with compressed air you need to know that serious accidents happen as a result of misuse and lack of know how.

Understanding the forces involved allows you to better understand that the air released from a blowgun or nozzle is essentially a jet stream – air at very high velocity. If pointed directly towards the skin , air can enter the blood stream and cause an embolism, blockage of a blood vessel which could be fatal. In most countries it is simply against the law to use air for purposes of cleaning as it also can deflect material and cause other accidents. The on-line makes you aware of the various hazards in using compressed air. but also provides you with guidelines and recommendations how to safely work with compressed air.

COMPRESSED AIR AND YOUR WORKING ENVIRONMENT

The noise level increases in a logarithmic scale, which means that the overall noise level is higher than the sum of the individual sound sources. Conversely, this means that when you eliminate individual sound sources. The reduction is perceived as larger than it really is. The best example of this is a leakage. A single leakage may not emit enough sound to be considered disturbing but hundreds- and sometimes thousands of leakages can create very high sound levels. Eliminating leakages, reducing blowing pressures and volume, using silencers to valves and cylinders can very quickly reduce the overall sound level in the workplace. You will get positive response from personnel immediately. From your own experience you probably recognize the positive effect of an eliminated source of sound that you had gotten used to. The on-line course describes what you can do to eliminate or reduce sound sources. It will lead to an improved working environment with less risk of hearing impairments.

COST & PRODUCTION

COST & PRODUCTION

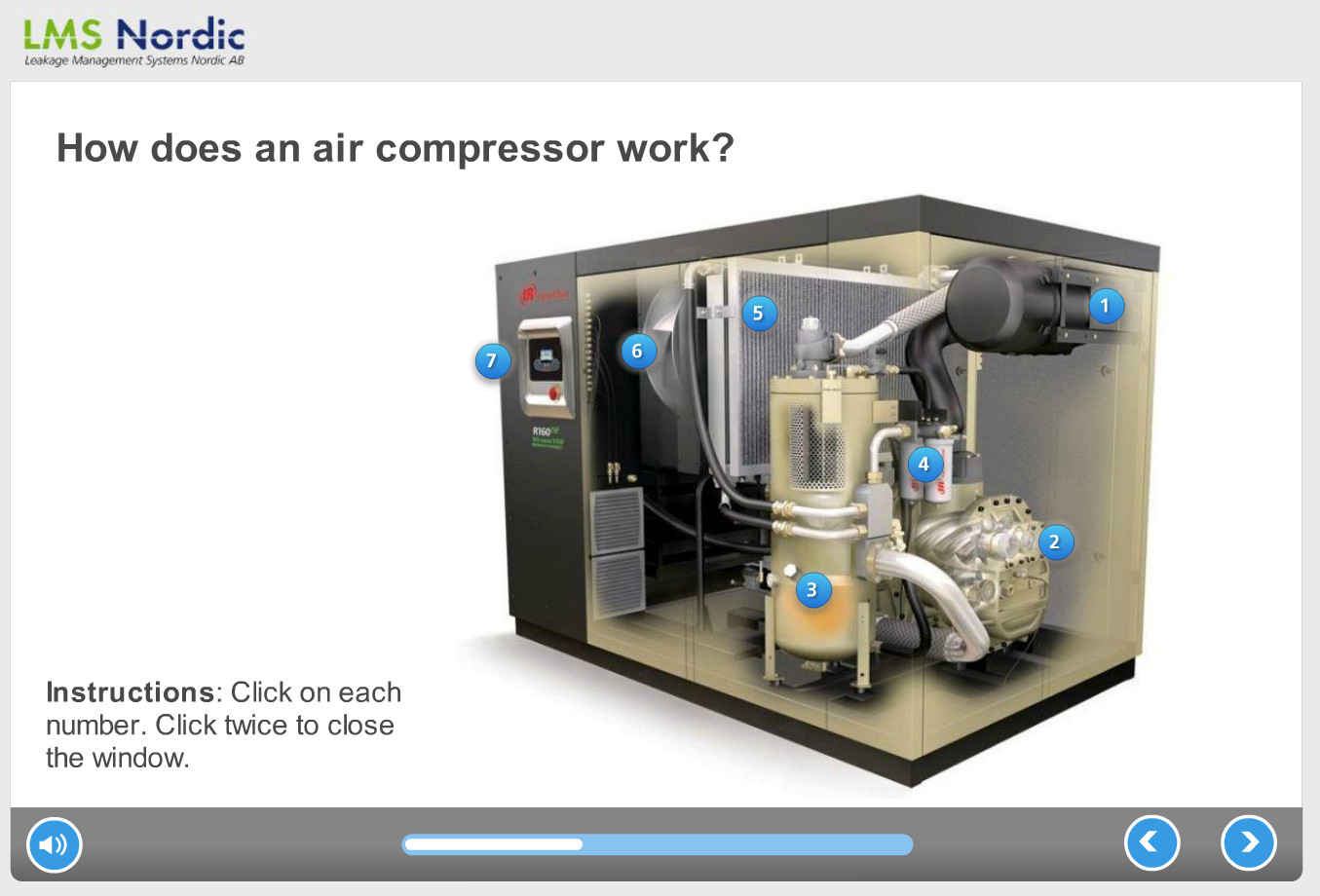

Not many people know how the compressed air is actually produced and what is involved in the delivery of compressed air in a factory. This is the main reason why most people are surprised about how expensive compressed air really is to use. Understanding how the compressed air system works and how a compressor works helps to understand why compressed air is so expensive. It may be obvious that the compressor does what it says, compresses the air . However, the compressed air normally needs to be dried and filtered. In order to produce the air as efficiently as possible you may need systems to control the running of the compressors and receivers to store the air. A compressed air system is for most companies a considerable investment that also needs to be serviced at regular intervals in order to function efficiently. The course explains the process and system in an easy to understand manner without getting too technical.

THE COST AND PRODUCTION OF COMPRESSED AIR

To produce compressed air is an expensive and ineffective process. To achieve real energy savings the cost of compressed air must be made understandable and preferably accountable. Many people know that compressed air is expensive. Most people however do not know that the annual cost of producing one cbm per minute is more than € 10.000. A single leakage 1 mm in diameter costsapprox. € 770 per annum. In most companies 20-50% of the produced air is wasted. Primarily through leakages. Misuse, artificial demand, too high pressure, poorly engineered blowing applications make up for the rest. It is not uncommon for this to cost several hundred thousand sometimes millions. Much of this waste can easily be avoided by simple guidelines and training at a very low investment.

LEAKAGES & OPTIMISATION

The combination of finding and repairing leakages and optimising applications represents almost 70% of the existing savings potential in a compressed air system. They are the two measures that have the shortest return on investment. Normally within 6 months. There are several sections in the course that provides the operator with suggestions and tips on how to quickly identify and perform actions on machines and workplace. If we manage to get every operator to fix just one leakage or reduce the pressure, the cost of the course will be paid for in a single day. If every operator contributes with just his or her part the total effect of these actions will be enormous. It is exactly this effect that most energy- and environmental managers have requested. A simple, straightforward course that provides know-how and practical suggestions that leads to motivated personnel and real results.