This machine is sold

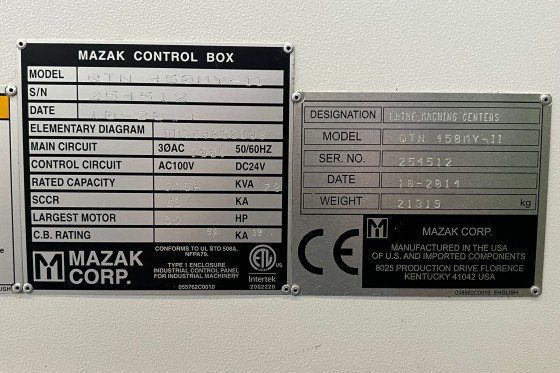

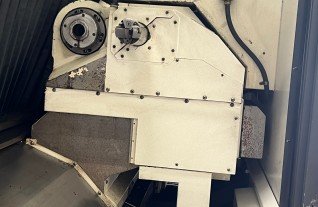

CNC Lathe with y-axis MAZAK - Quick Turn NEXUS 450 MY

MACH-ID 7087| Make: | MAZAK |

| Type: | Quick Turn NEXUS 450 MY |

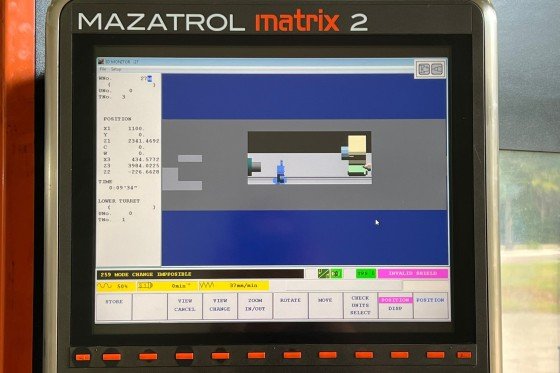

| Control: | Mazatrol Matrix Nexus |

| Year: | 2014 |

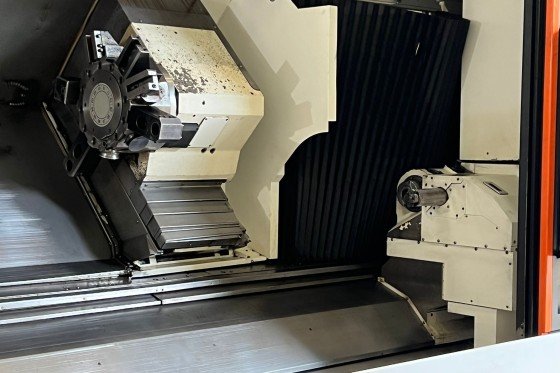

Ideal for the energy, heavy vehicle, and other large component industries, the Quick Turn Nexus 450-II MY and optional tailstock-mounted Long Vertical Mill, which features a 1,150mm boring bar with a special bolt-on angle head, can deliver deep-hole boring to depths of 1,039mm and perform inside diameter milling operations, such as internal keyways and internal drilling. The machine’s rigid construction also provides high-precision machining over long periods of time.

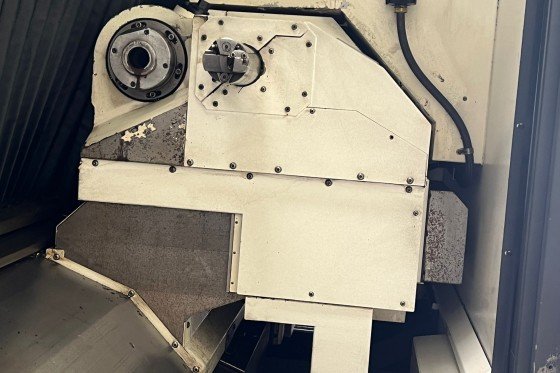

The Quick Turn Nexus 450-II MY’s headstock features a 457mm chuck, mounted on a 40 kW with 2,000rpm integrated spindle motor for heavy-duty metal removal. The spindle also serves as a C-axis, capable of being indexed at 0.0001° increments to accurately position parts for square facing and slotting cuts and precisely drilled holes. Additionally, the C-axis spindle is a full-function CNC controlled axis for milling.

The machine also uses a 12-position drum turret, and 7 kW with 4,000rpm rotary tool spindle for milling, drilling, and tapping operations, allowing many processes to be completed in a single machine cycle.

Package with 12 driven tools

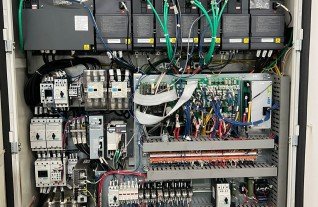

Filtration & Coolant system

Tailstock mounted deep-hole drilling & milling

Boring bar with angle head

Steady rest

Specifications

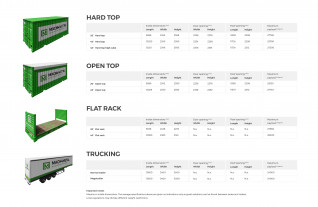

Dimensions (Estimate)

Please Note: The information on this page has been obtained to the best of our ability and belief, and from the manufacturers where possible. It is given in good faith, but its accuracy can not be guaranteed. Accordingly, it will not form a representation or constitute contractual terms. We advise you to check any vital details!

Ideal for the energy, heavy vehicle, and other large component industries, the Quick Turn Nexus 450-II MY and optional tailstock-mounted Long Vertical Mill, which features a 1,150mm boring bar with a special bolt-on angle head, can deliver deep-hole boring to depths of 1,039mm and perform inside diameter milling operations, such as internal keyways and internal drilling. The machine’s rigid construction also provides high-precision machining over long periods of time.

The Quick Turn Nexus 450-II MY’s headstock features a 457mm chuck, mounted on a 40 kW with 2,000rpm integrated spindle motor for heavy-duty metal removal. The spindle also serves as a C-axis, capable of being indexed at 0.0001° increments to accurately position parts for square facing and slotting cuts and precisely drilled holes. Additionally, the C-axis spindle is a full-function CNC controlled axis for milling.

The machine also uses a 12-position drum turret, and 7 kW with 4,000rpm rotary tool spindle for milling, drilling, and tapping operations, allowing many processes to be completed in a single machine cycle.

Package with 12 driven tools

Filtration & Coolant system

Tailstock mounted deep-hole drilling & milling

Boring bar with angle head

Steady rest