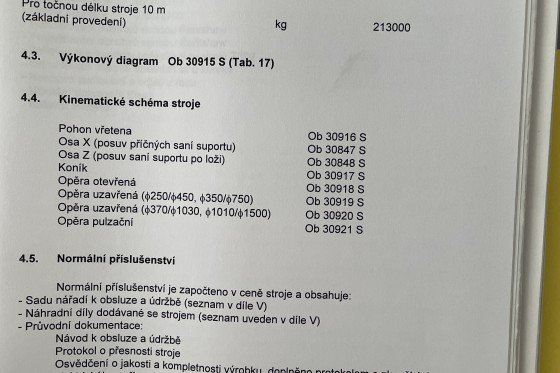

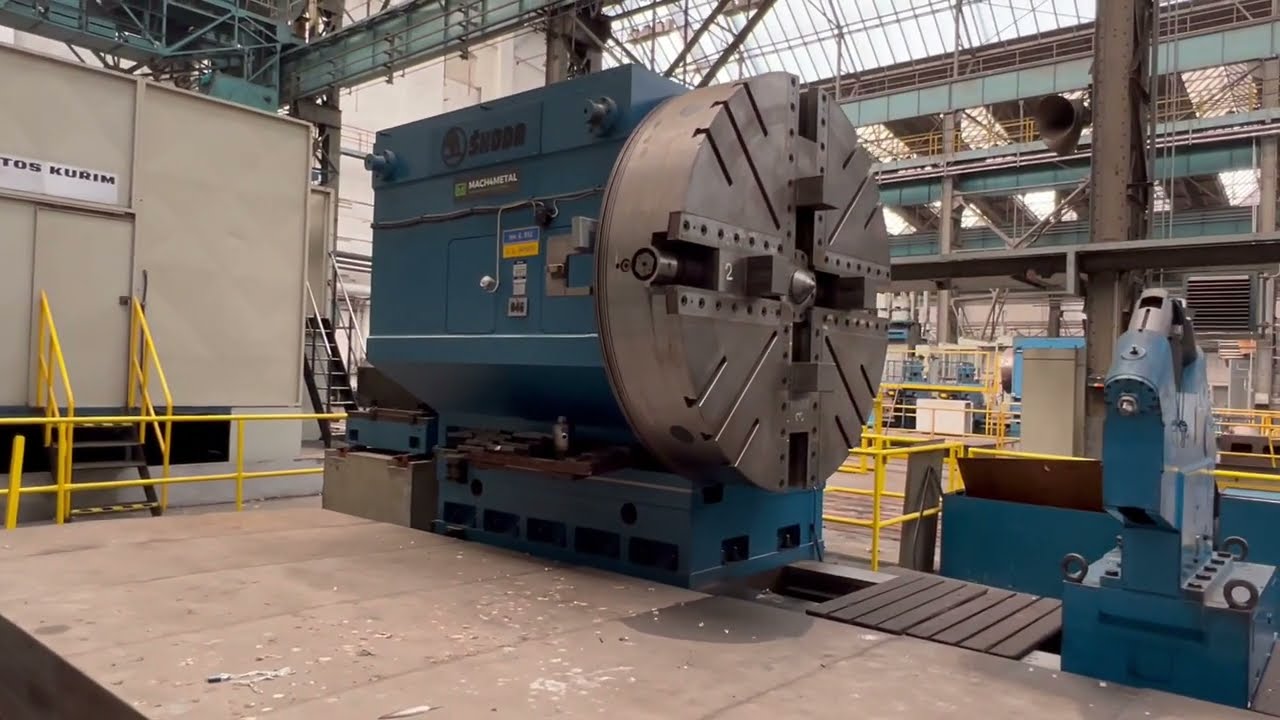

CNC lathe SKODA - SR3 - 220 CNC

MACH-ID 7110| Make: | SKODA |

| Type: | SR3 - 220 CNC |

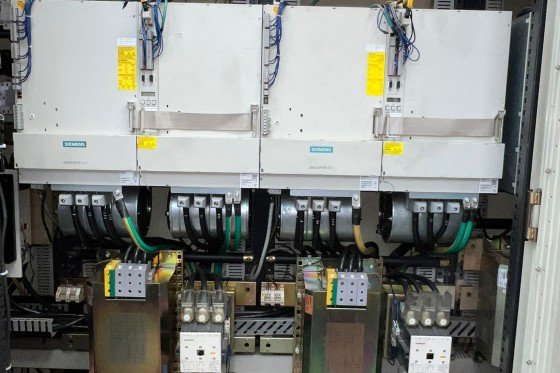

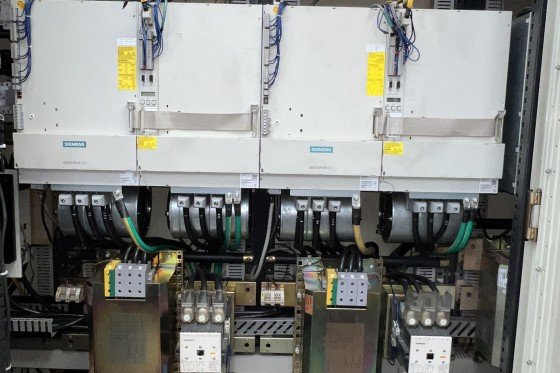

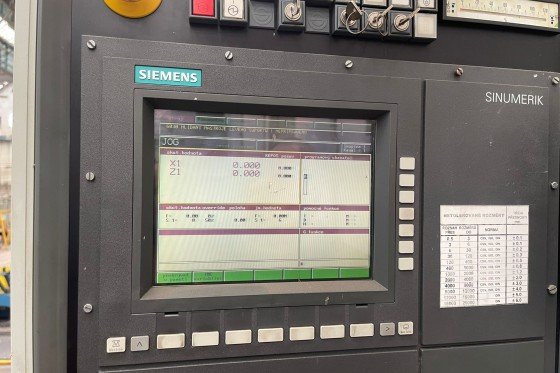

| Control: | Siemens 840 |

| Year: | 1997 |

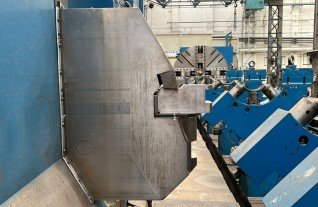

- Double carriage support with double lamella tool holder capto sandik

- Double carriage is Hydrostatic

- Double SIEMENS 840 control on each carriage platform

- 6 units Steady rest open C-Type

- 2 units lamella slide inserts

- 8 units heavy tailstock centers

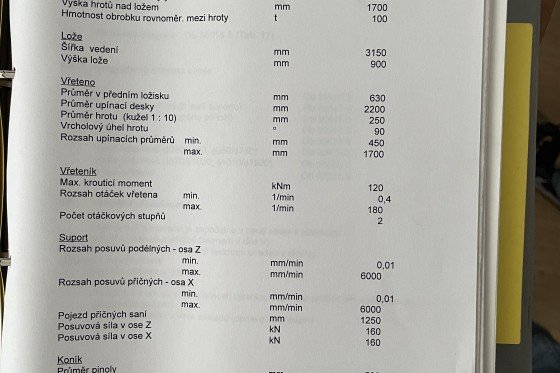

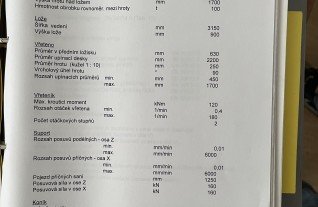

Specifications

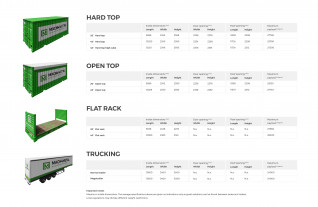

Dimensions (Estimate)

Please Note: The information on this page has been obtained to the best of our ability and belief, and from the manufacturers where possible. It is given in good faith, but its accuracy can not be guaranteed. Accordingly, it will not form a representation or constitute contractual terms. We advise you to check any vital details!

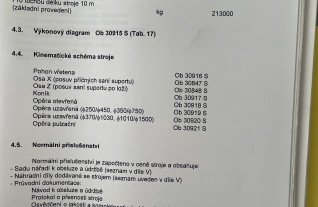

• The machine is placed on a concrete foundation making possible precise positioning of individual machine parts and retention of reaction forces from moving parts and cutting forces.

• The lathe bed of grey cast iron including four or five guideways is fitted onto the foundation block by means of anchoring bolts allowing for bed levelling in both horizontal and vertical directions. The guideways for tailstock and steadies are lined with hardened bars; the saddle guideways are protected by telescopic covers.

• The headstock body is a grey-iron casting with the spindle mounted in roller bearings or a combination of radial hydrostatic and axial roller bearings. The temperature-stabilised spindle is powered by an controlled AC drive. The gearbox includes gears wheels in constant engagement and a hydraulic system of speed step changing. Attached to the headstock is a removable faceplate with 4 or 8 independently controlled clamping jaws.

• The carriage can traverse along the tailstock and steadies. The longitudinal feed mechanism is facilitated by two preloaded pinions, feed in the in the crosswise direction by means of a ball screw in combination with pre-stressed nut. The carriage and cross slide use a combination of hydrostatic and rolling-contact mounting. The guideways are lined with plastic material. •

The tailstock traverses along the two rear guideways. The quill is provided with elastic seating in axial direction compensating temperature dilatations and indication of the axial force on the tip. The quill extension speed is variable. • The machine control system is fitted taking into account the customer preference (SINUMERIK 840C). • The machine control panel is located on the carriage platform.

• The machining sector can be provided with a cover